Repair / Refurbish

IEC offers full service repair and refurbishment of our slip rings. We will perform a complimentary evaluation and contact you with a repair estimate for your unit. Our basic repair includes disassembly, full cleaning of all components and replacement of those wearable parts needed including brushes, seals, bearings and o-rings.

If you have a unit in need of repair, please return the unit to:

IEC Corporation

Attn: Repair Department

3100 Longhorn Blvd.

Austin, Texas 78758-7696 USA

512.836.0547

All units repaired or refurbished include an additional 6-month warranty. The warranty period begins the date you receive the repaired unit back from IEC.

Standard turnaround for repairs is 2 weeks following our receipt of your approval of the repair.

Maintenance

Maintenance of your slip ring is very important. IEC recommends that all customers establish a maintenance schedule for all slip rings. Proper maintenance will greatly extend the life of the product.

As a general rule maintenance consists of removing brush dust from the slip ring every 500,000 revolutions. This can and will vary by model and by customer application. Below is a general maintenance procedure for the FM model.

Due to the harsh and unpredictable environments in which our slip rings are used, we highly recommend our customers maintain a spare unit pool. Proper use of spares provides peace of mind and gives you the flexibility to rotate your slip rings for maintenance or repair.

Maintenance Document

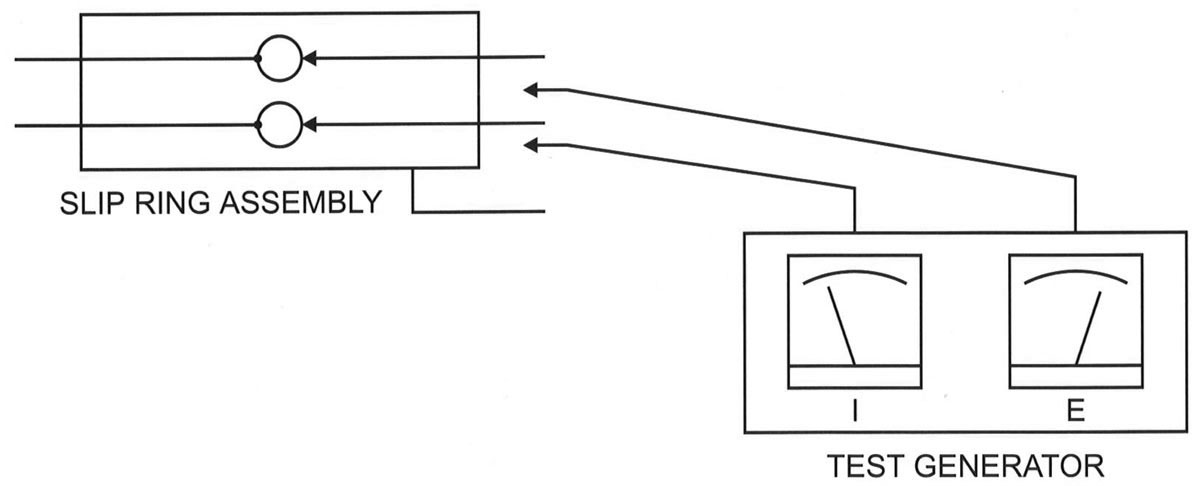

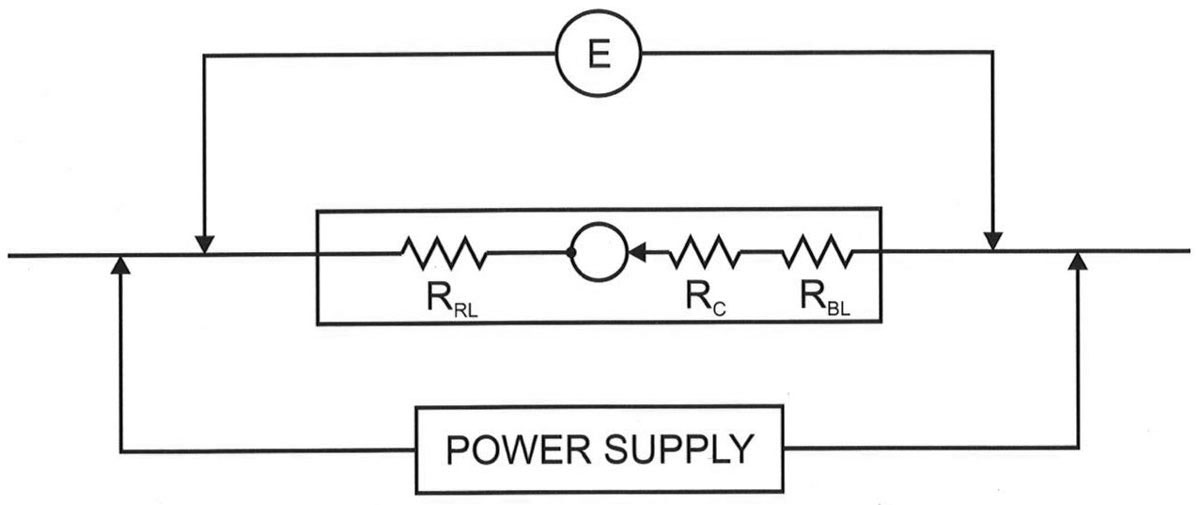

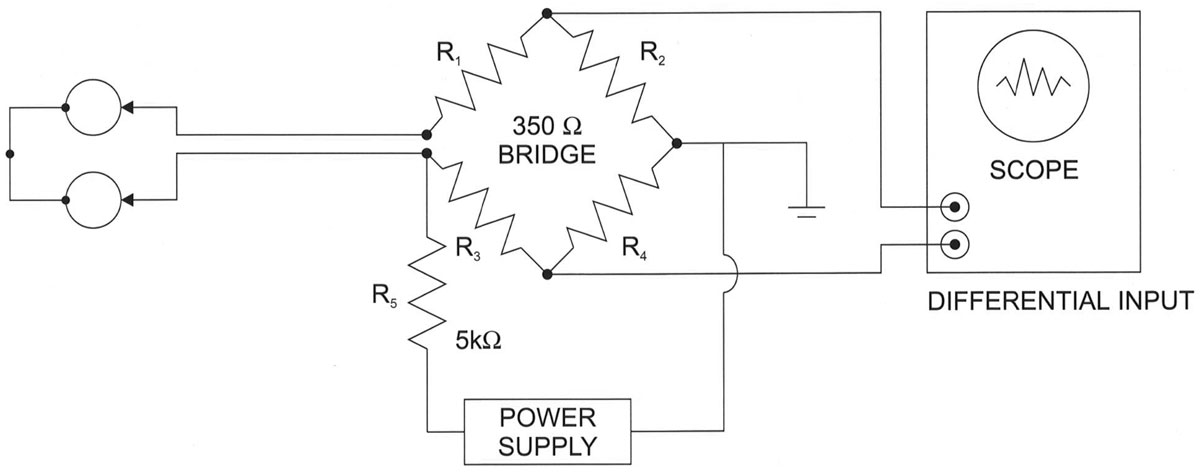

Electrical Testing

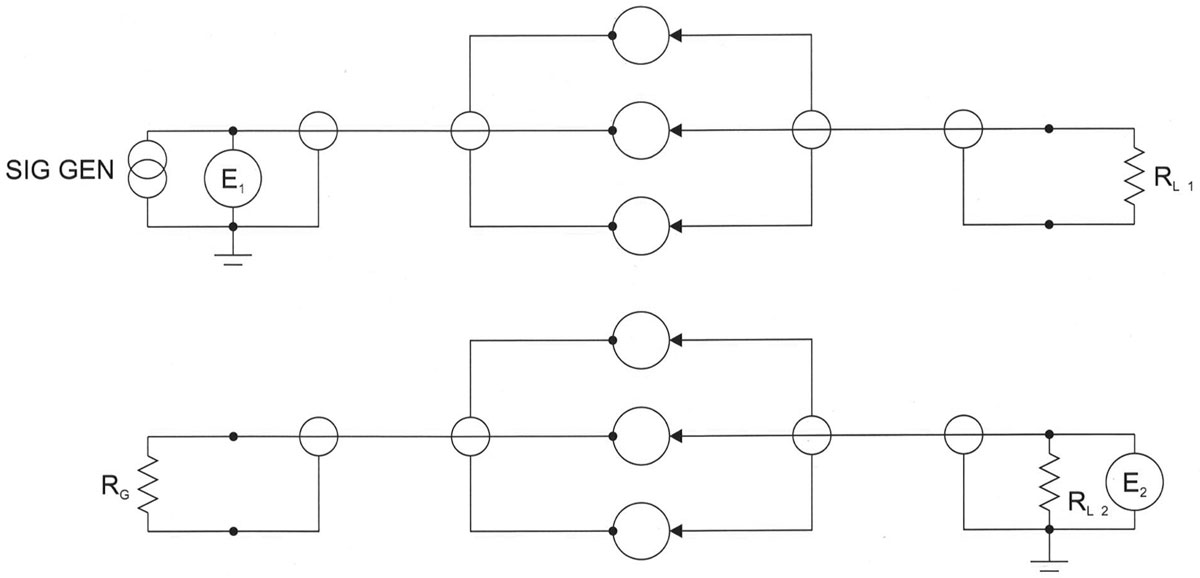

There are several ways to test a slip ring for any given electrical characteristic. The following schematics indicate IEC CORPORATION'S standard test circuits. The schematics are presented as equivalent circuits and do not contain the information required for test duplication. Test details and technical assistance will be gladly supplied by our testing department.

Test Circuit for Hipot and Leakage Resistance

Test Circuit for Series Resistance

- RRL = Ring Lead Resistance

- RC = Contact Resistance (2 milli-ohm Typ.)

- RBL = Brush Lead Resistance

- Rtotal = RRL + RC + RBL

Test Circuit for Slip Ring Noise

Test Circuit for Slip Ring Cross Talk

Frequently Asked Questions

What is your warranty period?

IEC offers a 12 month warranty on new units, and a 6 month warranty on all refurbished units.

When would I need a unit filled with synthetic oil?

Units filled with oil are beneficial in high humidity environments where condensation is likely to form. Please call our sales staff to discuss your unique needs.